Gripper® Wire Mesh Slings

Metal Mesh Slings that Hold On. And On. And On.

Unirope’s GRIPPER® metal mesh slings offer certain specialized advantages over other types of slings, especially if the load is being handled is abrasive or sharp-edged, unstable, hot or corrosive.

But perhaps a GRIPPER® Sling’s most important quality is its durability. The wire mesh offers excellent resistance to abrasive loads and as a result offers unsurpassed longevity.

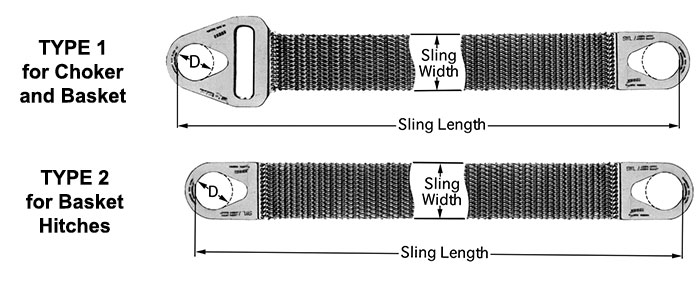

The choker and triangle fittings are joined to the metal mesh with stainless steel connector spirals. Using stainless steel connector spirals reduces the likelihood of failure at this point and assures complete flexibility between the fittings and the wire mesh.

Everything a Sling’s supposed to be. And then some.

Strong

The GRIPPER® Sling’s all steel metal mesh construction tolerates even the most abrasive loads without fear of sling failure. In addition, its environmental tolerance permits use at temperatures of up to 550 degrees F., and even higher when made of a special alloy.

Safe

Proof-tested at 200 per cent of its rated work load, every GRIPPER® Sling’s wide bearing surface improves load balance and gripping power. Unlike wire rope or chain slings GRIPPER® Slings won’t kink or tangle in use and as a result won’t shift or slip. What’s more, its woven spiral construction eliminates the danger of sudden failure that can occur with a rotting core in a synthetic sling or a weak link in a chain sling. All GRIPPER® products are manufactured in accordance with OSHA and ASME B-30.9 requirements.

Gentle

The GRIPPER® Sling’s interwoven, smooth spiral wires offer complete flexibility. So the sling conforms to the contours of its load, eliminating the dangers of gouging, marring, crushing or cutting so common with.

Saves time

Easy to rig a choke or basket hitch, the GRIPPER® Sling greatly reduces rigging and unhitching time.

Saves Money

The GRIPPER® Sling’s ability to outlast wire rope and web slings will cut your cost in the long run. You’ll also reduce the cost of damage to your loads and GRIPPER® Slings can be repaired and re-certified at a fraction of the cost of a new sling.

Versatile

The GRIPPER® Sling is ideal for handling all types of products, such as coiled strip, thin wall tubing, hot rolled flat bar stock, sheet steel, precast concrete beams, and objects subjected to hot or corrosive environments.

| Working Load Limit lbs (Design Factor 5:1) Heavy Duty – 10 gauge

|

||||||

|---|---|---|---|---|---|---|

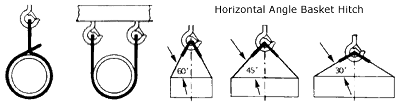

| Sling Width inch | D inch | Chocker (1) | 90° Basket | 60° | 45° | 30° |

| 2 | 1-3/4 | 1,600 | 3,200 | 2,700 | 2,000 | 1,600 |

| 3 | 2-1/2 | 3,000 | 6,000 | 5,100 | 3,800 | 2,800 |

| 4 | 2-1/2 | 4,400 | 8,800 | 7,480 | 5,600 | 4,400 |

| 6 | 2-3/4 | 6,600 | 13,200 | 11,225 | 8,400 | 6,600 |

| 8 | 4 | 8,800 | 17,600 | 15,000 | 11,250 | 8,800 |

| 10 | 4 | 11,000 | 22,000 | 18,700 | 14,000 | 11,000 |

| 12 | 4-1/2 | 13,200 | 26,400 | 22,440 | 16,800 | 13,200 |

| 14 | 4-1/2 | 15,400 | 30,800 | 26,180 | 19,600 | 15,400 |

| 16 | 4-1/2 | 17,600 | 35,200 | 29,920 | 22,400 | 17,600 |

| 18 | 4-1/2 | 19,800 | 39,600 | 33,660 | 25,200 | 19,800 |

| 20 | 4-1/2 | 22,000 | 44,000 | 37,400 | 28,000 | 22,000 |

|

(1) Applies to Type 1 slings ONLY |

||||||