Python® Ultra CP

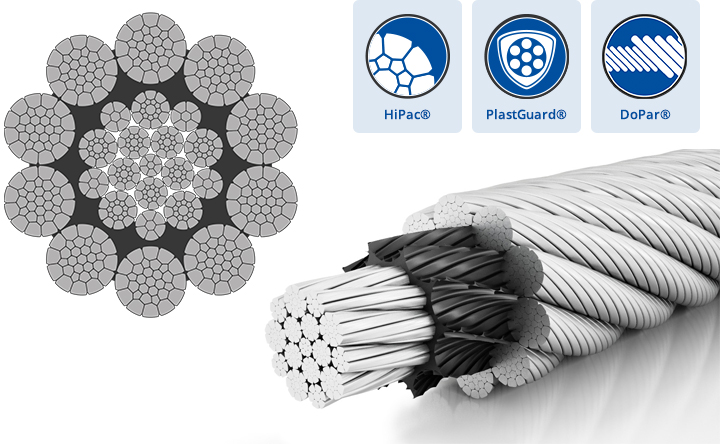

Super high strength crane and assembly rope (HiPac®, PlastGuard®, DoPar®)

- 10-strand fatigue resistant construction

- DoPar® – Double Parallel Inner- outer strands with

no internal cross-overs - HiPac® design to increase breaking strength

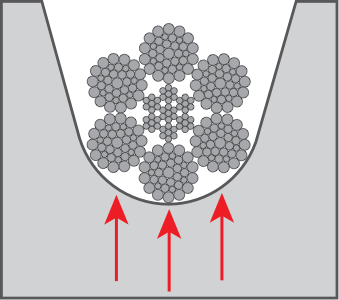

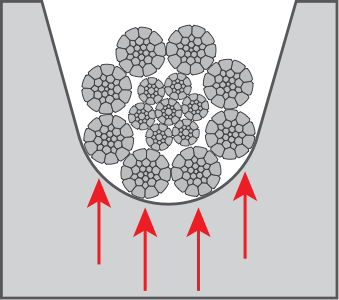

- Shaped outer wires for optimum sheave contact

- PlastGuard® avoids premature inner wire breaks

- Permanent lubricated core

Main Applications

Super high strength wire rope for high capacity overhead cranes including safety critical lifts and high risk applications.

Because of the HiPac® manufacturing technique, the availability of very specialized rope making machines and an innovative method to pastic coat the core this rope can be made up to 2-7/8” (76 mm) in diameter. Ideal for all “super cranes” Note that Python® ULTRA with ForcePac compaction can only be made up to a diameter of 1-1/4” (32 mm) but about 8-10% stronger. Well, you can’t have it all!

Rope Characteristics

Python®-Ultra CD is a super high strength rope. This rope has been developed so it can be used at fleet angles up to 4˚. The DoPar® construction in combination with a plastic coated core to lock-in lubricant ensures best bending performance.

HiPac® strand compaction results in an extreme smooth outer rope surface and the removal of most of the constructional stretch. This is an important feature if you require a low stretch rope for cables assemblies or applications where initial rope stretch must be as low as possible. Ultra CD provides a strength increase of up approximately 42-45% over regular 6-strand constructions. Refer to the conservatively calculated strength tables.

Python®-Ultra requires corresponding drum grooving directions; e.g. use a right hand lay rope if the drum is left hand grooved.

| 6-strand | 8-strand | |

|---|---|---|

|

|

Standard

EN 10264, 12385 where applicable

Breaking Strengths

Note: The maximum CAPACITY, WORKING LOAD LIMIT (WLL), or LINE PULL of the rope usually is 1/5 of the below stated values. For specific information consult the standards applicable to your rope application.

| Python® – Ultra | |||

|---|---|---|---|

| Minimum Strength tons of 2,000 lbs | |||

| Rope dia. inch | Ultra – EIPS | Ultra – EEIPS | Weight per foot lbs |

| 1 | 67.2 | 74.1 | 2.14 |

| 1-1/8 | 82.2 | 90.6 | 2.61 |

| 1-1/4 | 104.0 | 114.0 | 3.30 |

| 1-3/8 | 124.0 | 137.0 | 3.95 |

| 1-1/2 | 146.0 | 161.0 | 4.64 |

| 1-5/8 | 171.0 | 188.0 | 5.43 |

| 1-3/4 | 198.0 | 219.0 | 6.26 |

| 1-7/8 | 228.0 | 252.0 | 7.26 |

| 2 | 263.0 | 290.0 | 8.34 |

| 2-1/8 | 295.0 | 325.0 | 9.38 |

| 2-1/4 | 328.0 | 362.0 | 10.40 |

| 2-3/8 | 363.0 | 400.0 | 11.60 |

| 2-1/2 | 406.0 | 448.0 | 12.90 |

| 2-5/8 | 454.0 | 500.0 | 14.40 |

| 2-3/4 | 495.0 | 545.0 | 15.70 |

| 2-7/8 | 537.0 | 592.0 | 17.10 |

| Python® – Ultra | |||

|---|---|---|---|

| Minimum Strength in kN | |||

| Rope dia. mm | Ultra – 1960 N/mm² | Ultra – 2160 N/mm² | Weight per meter kg |

| 26 | 614 | 676 | 3.27 |

| 27 | 651 | 717 | 3.46 |

| 28 | 699 | 771 | 3.72 |

| 29 | 751 | 828 | 4.00 |

| 30 | 812 | 895 | 4.32 |

| 31 | 866 | 955 | 4.61 |

| 32 | 922 | 1,016 | 4.91 |

| 33 | 982 | 1,082 | 5.23 |

| 34 | 1,042 | 1,149 | 5.55 |

| 35 | 1,104 | 1,216 | 5.87 |

| 36 | 1,163 | 1,282 | 6.19 |

| 38 | 1,296 | 1,429 | 6.90 |

| 40 | 1,436 | 1,583 | 7.64 |

| 42 | 1,594 | 1,757 | 8.48 |

| 44 | 1,733 | 1,910 | 9.22 |

| 46 | 1,899 | 2,092 | 10.10 |

| 48 | 2,077 | 2,289 | 11.10 |

| 50 | 2,253 | 2,483 | 12.00 |

| 52 | 2,433 | 2,681 | 12.90 |

| 54 | 2,622 | 2,890 | 14.00 |

| 56 | 2,810 | 3,096 | 15.00 |

| 58 | 3,009 | 3,316 | 16.00 |

| 60 | 3,228 | 3,557 | 17.20 |

| 62 | 3,445 | 3,797 | 18.30 |

| 64 | 3,680 | 4,056 | 19.60 |

| 66 | 3,931 | 4,332 | 20.90 |

| 68 | 4,160 | 4,585 | 22.10 |

| 70 | 4,403 | 4,853 | 23.40 |

| 72 | 4,648 | 5,122 | 24.70 |

| 74 | 4,900 | 5,400 | 26.10 |

| 76 | 5,195 | 5,725 | 27.60 |

|

|