Engineering, Usage, Care, Inspection

Selection:

Choosing A Rope

Always consult the manufacturer before using rope when personal safety or possible damage to property is involved.

Make sure the rope is adequate for the job. Do not use too small a rope or the wrong type.

| Strength | Elastic Elongation | Weight | Application Factor:1 | UV Stability | Working Energy Absorption Capacity Ft. Lbs/Lb. Of Rope | Maximum Energy Absorption Capacity Ft. Lbs/Lb. Of Rope | Specific Gravity | Firmness 1=Firm |

Spliceability 5=very easy | Dielectric Strength MA Leakage @60KV DC |

Military Specification Number | |

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| PoBOn | 4.6 | <1.0 | 1.6 | 5 | G | 185 | 4,444 | 1.56 | ||||

| Crystalyne | 3.2 | 1.0 | 1.5 | 4 | G | 242 | 3,200 | 1.40 | ||||

| Ultrex Plus | 3.1 | 1.0 | 1.1 | 5 | E | 219 | 3,617 | 1.18 | ||||

| Maxibraid Plus | 3.0 | 1.0 | 1.1 | 5 | E | 160 | 2,645 | 1.18 | ||||

| Double Esterlon | 1.8 | 5.5 | 1.4 | 4 | E | 544 | 8,000 | 1.38 | ||||

| Polydyne | 1.9 | 6.9 | 1.2 | 4 | E | 1,040 | 9,700 | 1.24 | ||||

| Yalon | 1.5 | 7.7 | 1.1 | 5 | G | 910 | 10,100 | 1.14 | ||||

| Kernmaster | 1.7 | 6.0 | 1.2 | 10 | E | - | - | 1.23 | ||||

| Aramid Ropes | 3.5 | 1.0 | 1.5 | 4 | G | 225 | 2,395 | 1.40 | ||||

| Yalex | 1.9 | 5.8 | 1.4 | 5 | E | 545 | 11,025 | 1.38 | ||||

| Vectrus | 3.6 | <1.0 | 1.4 | 4 | G | 318 | 4,140 | 1.44 | ||||

| Poly Plus | 1.1 | 6.8 | 1.0 | 5 | F | 440 | 10,110 | 1.25 | ||||

| T-Line | 1.0 | 6.1 | 1.1 | 5 | E | 415 | 5,960 | 1.38 | MIL-R-24536 | |||

|

1 If used as a bull rope |

||||||||||||

| Fiber Comparison Data | Strength | Weight | Elastic Elongation | Water Absorption % @ 65%RH | Melt Point °F | Cost Ratio | |

|---|---|---|---|---|---|---|---|

| Nylon | 1.00 | 1.00 | 1.0 | 1.14 | 4.0 | 460 | 1.0 |

| Polyester | 0.90 - 1.10 | 1.20 | 0.6 | 1.38 | 0.4 | 480 | 1.0+ |

| Polypropylene | 0.55 | 0.80 | 0.9 | 0.91 | Neg | 330 | 0.8 |

| Polyethylene | 0.55 | 0.83 | 0.6 | 0.95 | Neg | 280 | 0.8 |

| Kevlar | 2.70 | 1.26 | 0.1 | 1.44 | 7.5 | 800* | 8.0 |

| Vectran | 3.80 | 1.26 | 0.1 | 1.44 | Neg | 620 | 22.0 |

| Zylon PBO | 5.40 | 1.40 | <0.1 | 1.56 | 0.6 | 1,200** | 60.0 |

| Manila | 0.30 | 1.10 | 0.5 | 1.38 | High | 275* | 0.9 |

* (Chars) |

|||||||

Usage:

Unreeling: Remove rope properly from reels to prevent kinking. The rope should be removed by pulling it off the top while the reel is free to rotate. To proceed in any other manner may cause kinks or strand distortion.

Handling: Never stand in line with rope under tension. If a rope fails it can recoil with lethal force. Synthetic rope has higher recoil tendencies than natural fiber rope. Reverse rope ends regularly. This permits even wearing and assures a longer, useful life. When using tackle or slings, apply a steady, even pull to get full strength from rope.

Caution: Overloading and Use of Working Loads:

Because of the wide range of rope use, exposure to the several factors affecting rope behavior, and the degree of risk to life and property involved, it is impossible to make blanket recommendations as to working loads. However, to provide guidelines, working loads are tabulated for rope in good condition with appropriate splices, in non-critical applications and under normal service conditions.

A higher working load may be selected only with expert knowledge of conditions and professional estimate of risk and if the rope has not been subject to dynamic loading or other excessive use, has been inspected and found to be in good condition and is to be used in the recommended manner and the application does not involve elevated temperatures, extended periods under load or obvious dynamic loading (see explanation below) such as sudden drops, snubs, or pickups. For all such applications and for applications involving more serious exposure conditions, or for recommendations on special applications, consult the manufacturer. Many uses of rope involve serious risk of injury to personnel or damage to valuable property. This danger is often obvious, as when a heavy load is supported above one or more workers. An equally dangerous situation occurs if personnel are in line with a rope under tension. Should the rope fail, it may recoil with lethal force. Persons should be warned against the serious danger of standing in line with any rope under tension.

In all cases where such risks are present, or there is any question about the loads involved or the conditions of use, the working load should be substantially reduced and the rope properly inspected.

Dynamic Loading Voids Normal Working Load:

Normal working loads are not applicable when rope is subject to significant dynamic loading. Instantaneous changes in load, up or down, in excess of 10% of the line’s rated working load constitutes hazardous shock load and would void normal working loads. Whenever a load is picked up, stopped, or swung there is an increased force due to dynamic loading. The more rapidly or suddenly such actions occur, the greater the increase will be. In extreme cases, the force put on the rope may be two, three or even more times the normal load involved. Examples could be picking up a tow on a slack line or using a rope to stop a falling object. Therefore, in all such applications such as towing lines, lifelines, safety lines, climbing ropes, etc., working loads as given DO NOT APPLY.

Users should be aware that dynamic effects are greater on a low elongation rope such as polyester than on a high elongation rope such as nylon, and greater on a shorter rope than on a longer one. The working load rations listed contain provision for very modest dynamic loads. This means, however, that when the working load has been used to select a rope, the load must be handled slowly and smoothly to minimize effect and avoid exceeding provision for them.

Example: A load of 3,500 lbs. is being lowered using 5/8 diameter Double Esterlon which has a maximum recommended working load of 4,000 lbs. With 15 feet of line payed out, the line is accidentally slipped, dropping the load one foot before arresting the fall.

Question: How much energy did the rope have to absorb, what was the maximum load on the rope, and has the rope been overloaded or damaged?

work done (Ft. Lbs.) – (weight)(length of fall) = 3,500 Ft. Lbs.

rated maximum working energy absorption

capacity = (weight of the rope in use)(working energy absorption capacity for the type of line being used)

From the data page: Double Esterlon has a working energy absorption capacity of 544 ft. lbs. per pound of rope and a weight of 13.7 lbs. per 100 ft. or 0.137 lbs./ft.

rated maximum working energy absorption capacity of 16 ft. of 5/8

Double Esterlon =(16 ft.)(544 ft. lbs./lb.) = 1,192 ft. lbs.

In this example, 2.19 lbs. of rope (16 ft. x 0.137 lbs./ft.) in use must absorb 3,500 ft. lbs., or 3,500 ÷ 2.19 lbs. equals 1,596 ft. lbs./lb. or rope. Using the graph on page 8 (Double Esterlon), the right column indicates ft. lbs. of energy absorbed in capacity per pound of rope. Corresponding to 1,596 ft. lbs./lb., you will find that the rope was loaded to approximately 48% of rated BS. From the data table, 48% of the 5/8″ diameter Double Esterlon’s strength (16,000 lbs.) is 7,680 lbs.

In this example the maximum working energy absorption capacity has been exceeded by nearly 3 times. The actual load on the rope reached 7,680 lbs., or 3,680 lbs. in excess of the maximum working load of 4,000 lbs. Although difficult to quantify, some degree of the rope’s integrity has been compromised and prudent safety practice would call for downgrading or discarding the line. If in our example the load had fallen 7 feet instead of 1 foot, the rope would have broken.

Abrasion: Avoid all abrasive conditions. All rope will be severely damaged if subjected to rough surfaces or sharp edges. Chocks, bits, winches, drums and other surfaces must be kept in good condition and free of burrs and rust. Pulley must be free to rotate and should be of proper size to avoid excessive wear. Clamps and similar devices will damage and weaken the rope and should be used with extreme caution. Do not drag rope over rough ground. Dirt and grit picked up by rope can work into the strands, cutting the inside fibers.

Chemicals: Avoid chemical exposure. Rope is subject to damage by chemicals. Consult the manufacturer for specific chemical exposure, such as solvents, acids, and alkalies. This is particularly true for natural fiber rope. Consult the manufacturer for recommendations when a rope will be used where chemical exposure (either fumes or actual contact) can occur.

Temperature: Effect on tensile strength. The tensile strength charts apply to ropes tested at normal room temperature (70°F). Ropes have lower tensile strengths at higher temperatures 30% (or more) lower at the boiling point of water (212°F) and continuing on down to zero strengths for nylon and polyester at 480°F and 300°F for polypropylene. Also, continued exposure at elevated temperatures can melt and part synthetic ropes or cause permanent damage.

Splicing: Join rope by splicing. Knots can decrease rope strength by as much as 60%. Use the manufacturers

recommended splices for maximum efficiency. Other terminations can be used but their strength loss with a particular type of rope and construction should be determined and not assumed.

Storage And Care:

All rope should be stored clean, dry, out of direct sunlight, and away from extreme heat. Some synthetic rope (particularly polypropylene, polyethylene, and aramid) may be severely weakened by prolonged exposure to ultraviolet (UV) rays unless specifically stabilized and/or pigmented to increase its UV resistance. UV degradation is indicated by discoloration and the presence of splinters and slivers on the surface of the rope.

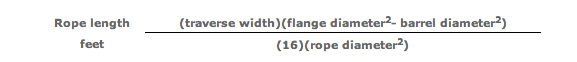

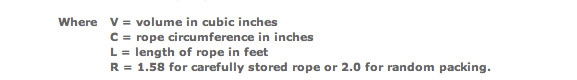

Formulas to determine reel and storage capacities:

Use inch reel dimensions.

Formulas to determine bin capacity: V=C ² xLxR

Inspection:Avoid using rope that shows signs of aging and wear. If in doubt, destroy the used rope. If there is any question, destroy the used rope. No type of visual inspection can be guaranteed to accurately and precisely determine actual residual strength. When the fibers show wear in any given area the rope should be respliced, eliminating the damaged area, downgraded or replaced. Check the line regularly for frayed strands and broken yarns. Pulled strands should be rethreaded into the rope if possible. A pulled strand can snag during a rope operation. Both outer and inner rope fibers contribute to the strength of the rope. When either is worn, the rope is compacted or hard which indicates reduced strength. The dielectric strength of rope in this condition is also reduced. |

|